How 130-year-old Kirloskars is staying relevant in the era of the fourth industrial revolution

In an exclusive in-depth interview with Kirloskar Brothers Limited Chairman and MD Sanjay Kirloskar, SMBStory reveals what it takes to build a sustainable business that creates lasting value for customers.

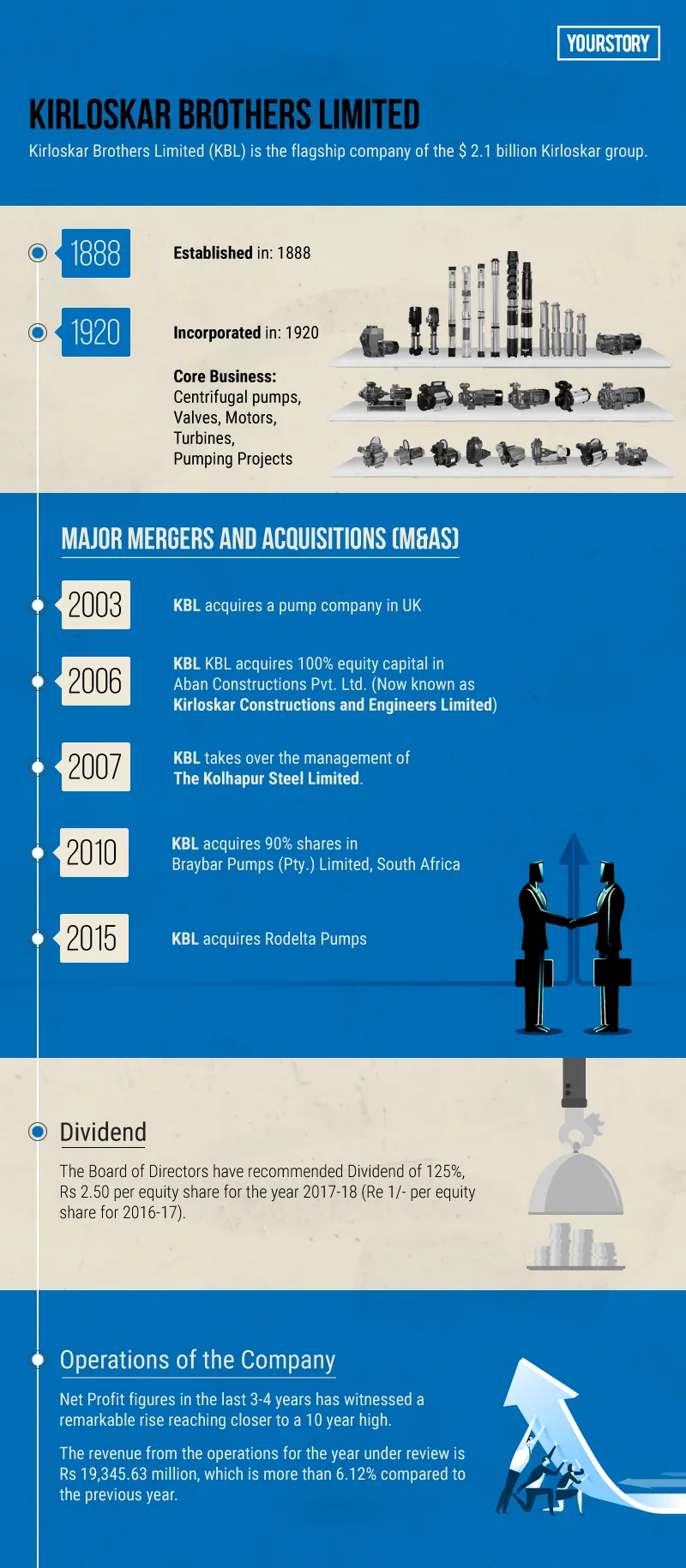

In 1888, more than 130 years ago, Laxmanrao Kirloskar left his job to get into the business of selling bicycles and windmills with his brothers Rammohanrao and Vasudevrao in Belgaum. As someone who was passionate about machines, Laxmanrao wanted to build his own.

In 1901, he introduced his first product, the chaff cutter. The company, Kirloskar Brothers, which was the genesis of the $ 2.1 billion Kirloskar Group, brought out its second product, the iron plough, in 1903.

The first product of Kirloskar Brothers.

It was a revolutionary product of its time. The prevalent belief then was that the use of an iron plough would poison the soil in the fields. Laxmanrao, nonetheless, persisted and found supporters to sell his plough. And as they say, there was no looking back. It went on to become a tough competitor to the British ploughs.

A model of the iron plough at the KBL's museum.

In today’s days of angel investors that help take businesses to the next level, it is interesting to note that when Laxmanrao was down and out, he too received a similar help, which according to Sanjay Kirlokskar, Chairman and MD of Kirloskar Brothers Limited (KBL), was no less from an angel.

“Rambhau Ginde supported my grandfather with the much-needed money to keep the business going. He was truly his angel,”

Sanjay tells me while recalling the past struggles of the people who built this more than 100-year-old organisation. On January 15, 1920, Kirloskar Brothers was officially registered as a legal entity, Kirloskar Brothers Limited.

At a grand function on March 10 in Pune to celebrate this milestone, Sanjay Kirloskar had especially invited the descendants of the Ginde family to facilitate them.

Sanjay Kirloskar

The function was also marked by the presence of veteran industrialist Ratan Tata, who unveiled the company’s revised ‘Code of Ethics’ to strengthen its century-old values. Being an Indian multinational firm, Sanjay Kirloskar feels it is important that the company has a uniform code of values and ethics across all its offices everywhere in the world.

In fact, most of the promotions and incentives are given on the basis of how high an employee scores in the Code of Ethics online test.

Global leader in fluid pumping tech

A day after the centenary celebrations, I met Sanjay Kirloskar at KBL’s office in Pune to talk to about the organisation’s past, present, and future.

Dressed in a blue shirt with the Kirloskar logo (just like all the other employees), Sanjay Kirloskar exudes a quiet strength. At the same time, he makes his visitors at ease with his unassuming manners.

The formal interview quickly morphs into a scintillating conversation where he gives me glimpses of the company’s 130-year-long journey, the future ahead, and a peek into his personal life -- the book he is reading and (you will be surprised) the new season of an HBO series that he is eagerly awaiting.

KBL, the flagship of the $ 2.1 billion Kirloskar Group, is today one of the most admired engineering firms both in India and the world. Synonymous with pumps, KBL is a global leader in fluid pumping technology. It has 18 manufacturing facilities supplying to more than 165 countries spanning across more than eight sectors, including power, oil & gas industry, building & construction, irrigation, marine & defence, and retail pumps. It has an 80 percent market share in the UK’s water companies, and is also Britain’s largest pump manufacturer through its subsidiary, SPP Pumps.

Global iconic buildings like the Sydney Opera House, the Burj Khalifa in Dubai, and many others in London and Egypt use Kirloskar pumps for critical applications.

An advertisement showcasing different products of the company.

Besides executing the largest pumping scheme at the Sardar Sarovar Narmada Nigam in Gujarat, which provides drinking water to more than 30 million Indians, KBL’s critical pumps are also used in the country’s nuclear fusion programme. These pumps are used for cooling the prototype reactor.

Today, KBL provides drinking water to more than 35 percent of India’s population while pumping water to more than 60 percent of irrigable land for turnkey projects that include river linking, river lifting, water treatment, and irrigation projects.

“The aim was to ensure that India could rely on an Indian-owned company for all its requirements,” Rama Kirloskar, daughter of Sanjay Kirloskar, said in her address at the centenary celebration. Rama serves as MD of Kirloskar Ebara Pumps Limited, a joint-venture between Ebara Corporation, Japan, and KBL.

KBL’s glorious history

It is interesting to hear the history of the organisation from someone so close to it. Sanjay Kirloskar narrates an incident from his father Shantanurao Kirloskar’s time, which is worth noting here.

Around the time his father came back from studying at MIT in 1926, the import duty on components was very high, higher than the finished products because the British did not want machines to be manufactured in occupied India. “Under my father, KBL found innovative means to make cheaper and better products,” says Sanjay.

Just before World War II, the British asked KBL to manufacture ammunition to support its war efforts. Shantanurao Kirloskar felt it would be a short-sighted move, and instead opted to manufacture machine tools since that could be used during the war as well as after the war.

India's first Prime Minister Jawaharlal Nehru using the iron plough.

This helped the company a great deal and as the business grew, KBL diversified in the 1940s into various allied businesses, many of which became big enough to be converted into different companies with the same Kirloskar logo.

However, the business also saw a number of challenges through the years. Sanjay recounts the time in 1947, when his father took responsibility for a faulty product and recalled the entire sugarcane crushers.

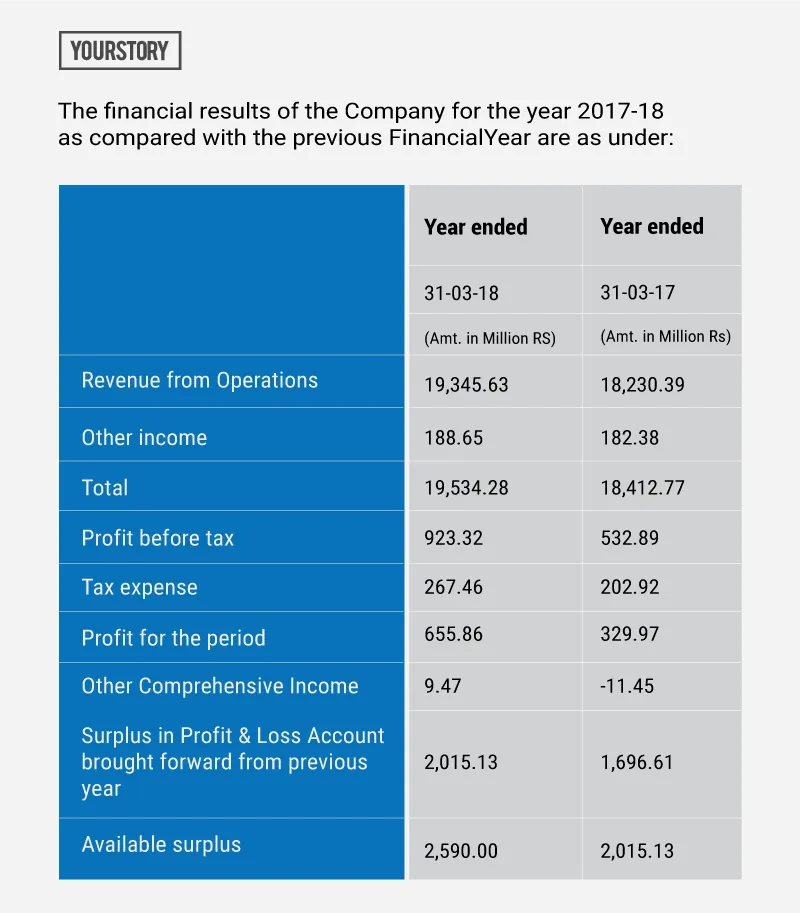

“This led to a massive loss, and the company was unable to pay dividends to its shareholders,” he says, adding, “After that, the company had not failed in paying dividends since 1938. In fact, the company has skipped dividends only five times in the last 100 years, that too during the times of the great depression.”

Into the fourth industrial revolution

When Sanjay Kirloskar took over the reins from his father in 1983, India was yet to be free from the Licence Raj. Until 1991, before the economic liberalisation policy brought in by the government, there was a condition that one could carry on with one’s business only if they agreed that they could make a certain number of products every year. The policy mandated that a business could not import any machinery (at least not the ones that were already being manufactured in India) to manufacture its products. Says Sanjay,

“At that time, the challenge was more in terms of ease of doing business and lack of transparent economic policies. Today, the challenge is to see which way is technology moving, whether it is in electronics, Artificial Intelligence, or tele-communications so that we can give the customer the best product that will ensure them peace of mind.”

He says businesses like his with such an old legacy have to be on top of things if they want to remain the leaders and be relevant in this new era of automation. He remarks,

“Whatever technology advances are happening in the world today, you either incorporate it or rule it out. There’s no choice. And you hope there’s no Uber or Airbnb coming into your space and disrupting it. You have to keep your eyes open.”

KBL operates the largest 3D printers in mainstream manufacturing of pumps. They have also introduced Artificial Intelligence (AI), and self-learning systems that work with sales teams and end-users to select, customise, and perform all application engineering around existing products.

Alok and Rama Kirloskars

“The products themselves are smarter with IoT-enabled pumps and factories with IoT-enabled machines. Our technicians and field service engineers are more effective through the introduction of Virtual Reality. We have also introduced Augmented Reality for hands-on service. All these investments have been done so that we can respond to customers faster,” said Alok Kirloskar, Sanjay Kirloskar’s son, in his address at the centenary celebrations. Alok is MD at SPP Pumps, a subsidiary of KBL.

Manufacturing woes

As someone who is entrenched into the manufacturing ecosystem of the country as a global leader, it is interesting to hear Sanjay Kirloskar’s views on what ails India’s manufacturing sector.

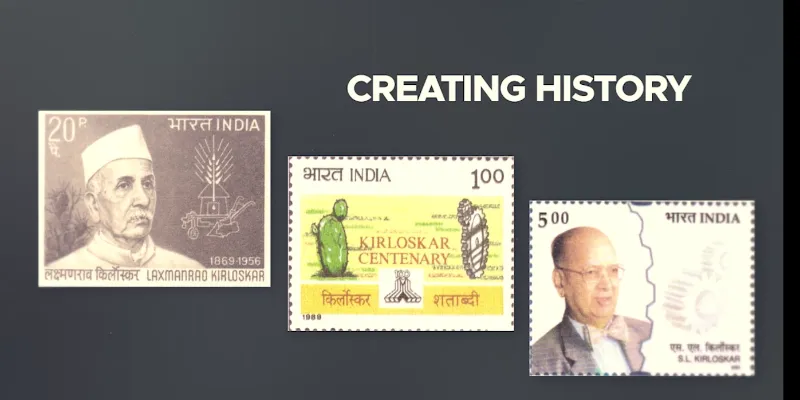

The Indian Postal Service postage stamps that depicts Laxmanrao and Shantanurao.

“There are global tenders that say ‘no Indian’ or, for that matter, ‘no Chinese companies’. On the other hand, countries like Saudi Arabia say that if any global company wants to enter its markets they will have to provide 80 percent of value addition on their soil. Bahrain has a similar clause. All these countries want industries to develop in their regions,” says Sanjay.

In India, however, the policies mandate only 20 percent of value addition (which is mostly around packaging and labelling) from a foreign company. “If we want Make in India to be successful, then 80 percent of value addition should be the norm. Why is Airbus or GE making in China? The Chienese want that technology and it is simply saying, ‘if you want to participate in my market, you will have to play by my rules’. Isn’t that what America is doing too?” he asks, adding, “I’d like to see the clarity in India that America or China have, or for the matter that Saudi Arabia has.”

With a GDP of $ 2.3 trillion and the world’s ninth largest economy, India’s manufacturing accounts for only 16 percent of the country’s GDP. India represents only two percent of the world’s manufacturing output, a tenth of what its neighbour China contributes.

In his book Kranti Nation: India and the Fourth Industrial Revolution, economic analyst Pranjal Sharma talks about how the emerging technologies, including AI, ML, robotics, cloud computing, 3D printing, blockchain, IoT, and so on, are spearheading the fourth industrial revolution.

In the book he gives examples of this fourth industrial revolution from 10 different sectors that also includes manufacturing. He brings out KBL’s successful implementation of 3D printing, showing how Indian industry is being transformed by the fourth industrial revolution.

Failure lessons

According to Sanjay Kirloskar, the reason KBL has stayed relevant through the years is because of its sharp focus. But, isn’t there a temptation to diversify into a different segment, I ask. “I have burnt my fingers too many times. We grew from pumps into systems supply and we were working with a large number of Engineering Procurement Construction (EPC) contractors but did not like the way they operated. It was a big mistake and set the company back by 10 years,” he says candidly.

Sanjay says at that time he felt the company needed to be in it to give a better solution to the customers. He adds with a chuckle,

“Like they say, the grass is always greener on the other side. But sometimes it is just astroturf.”

Over the years, as the head of a behemoth organisation, Sanjay has faced different challenges, including a public spat with his brothers that involved a legal battle over property and business disputes.

The Kirloskar family with former PM Rajiv Gandhi.

The only way he overcomes these challenges, he feels, is the lessons he learnt from his father.

“My father once told me, ‘a lot of people will tell you that you are doing a great job. But remember, as the MD the impact that you create will be seen only five years later.’ What he meant was think long-term and create value that will last longer than you. Do not go in for instant gratification.”

He states that he gave his children, Alok and Rama, the option to choose their own career paths as he did not want to burden them with any great expectations. “I told them, in one family you can’t expect people to be interested in the same thing again and again. So, you do what you want. It is only then will you reach the top.”

Sanjay Kirloskar

Though he himself ducked the question on whether he wanted to pursue a different career, Sanjay says he takes joy in many other things in life. He likes reading, and right now he is reading Homo Deus: A Brief History of Tomorrow, a follow up of Yuval Noah Harari’s seminal Sapiens: A Brief History of Humankind. “I must say it is a difficult read. By the time I finish reading I’m afraid I’ll become a vegetarian,” he says with a laugh.

Meanwhile, he is awaiting the next season of Game of Thrones due in April. “It is so much like the epic Mahabharata,” he says referring to the palace intrigues portrayed in both. “You realise that the more the things change, the more they remain the same,” he adds.

When everything is said and done, it is this sagacious approach to life and work that perhaps counts in the end.

1553256833936.png?mode=crop&crop=faces&ar=2%3A1&format=auto&w=1920&q=75)