From selling 10 clocks to Rs 65 Cr turnover, story of India’s 2nd largest clock company

Started in 1996, Jayesh Shah’s Sonam Clocks grew from a small shop in Mumbai to a big manufacturing enterprise in Morbi, Gujarat. Today, the company manufactures up to 15,000 wall clocks, and is seeing 50,000 clock movements a day.

In 1996, a small-time wall clock retailer in Mumbai decided to start manufacturing clocks. The young and enterprising Jayesh Shah didn’t want to continue selling just 10 clocks a day - he wanted his own wall clock brand.

Working out of a 250 square feet shop, he began purchasing raw materials, building the clocks, and selling them locally. Jayesh managed everything single-handedly, and invested his profits back into the business.

Thus began the journey of Sonam Clocks, currently India’s largest producer of clock movements and second largest manufacturer of wall clocks, after Ajanta Orpat.

The hub of clocks manufacturing

After starting small in Mumbai, Jayesh quickly realised he should shift his business to Morbi in Gujarat, which is the hub of clocks manufacturing in India.

He knew that in Morbi, clock companies had easy access to skilled labour with experience in clock manufacturing as well as raw material and supplies.

“Further, the distance between Morbi and Mundra port is 200 kms, which facilitates ease in import and export. Morbi is also well-connected with roadways,” Jayesh (52) tells SMBStory in an exclusive interview.

He believed these factors would boost cost efficiencies in procuring manpower and raw material, as well as reduce the cost of logistics.

In the same year, he promptly moved his clock manufacturing business, which was named Riddhi Enterprise back then, to Morbi.

Jayesh Shah, chairman and managing director, Sonam Clocks

To begin with, Jayesh rented a 1,000 square feet facility, put together a workforce, and began making 250 clock pieces a day. But soon, he realised this wasn’t enough, and so he purchased a 15,000 square feet unit in 1997.

A building of this size was still insufficient to accommodate Jayesh’s entrepreneurial vision, which was expanding rapidly. In 1998, he took up a two lakh square feet production unit on the Morbi-Rajkot Highway.

In 2001, the company was incorporated in the name of Sonam Clock Private Limited, and became a well-known wall clocks and clock movements manufacturer.

Lessons learned the hard way

Clock makers competed on the basis of quality of products, pricing, and timely delivery. Sonam Clocks, which was highly dependent on suppliers of raw materials and packaging, was exposed to the risk of fluctuations in the prices and availability of these supplies.

“Initially, we did not have any supply agreements with the vendors. All the raw materials were purchased from various vendors on an order-to-order basis. Upward fluctuations in prices resulted in increased cost of production. This would adversely impact our business and profitability,” he says.

Jayesh learnt his lesson, and realised the importance of developing mutually-beneficial and long-term relationships with suppliers. He grew to understand how strategic supplier relationship management could help improve Sonam’s performance across the supply chain, generate greater cost efficiency, and enable the business to scale up.

The company then began performing continuous project reviews and implemented timely corrective measures in case of any issues in manufacturing. It also ensured technology upgradation when required.

The Sonam manufacturing facility in Morbi

Business model

Till 2014, its exports accounted for 70 percent of the company’s wall clock business. “Demand slowdown in the global market prompted us to shift greater focus on the domestic market. The local market grew to contribute 70 percent of our wall clock sales. And 30 percent of our sales started coming from exports,” Jayesh says.

He claims Sonam Clocks has over 30 percent market share in India’s total exports of wall clocks and clock movements.

In 2018, the company was listed on the National Stock Exchange (NSE)’s SME exchange, and raised Rs 10 crore from the market.

“Today, we have a 650-member workforce, out of which 90 percent to 95 percent are women. We make 12,000 to 15,000 wall clocks and 50,000 clock movements per day,” he says.

He claims Sonam Clocks has a network of over 150 distributors and 35,000 retailers, exporting to over 27 countries across four continents

The company ended 2018-19 with Rs 65 crore revenue. It is aiming to grow to Rs 150 crore revenue by 2022.

Jayesh maintains the ability to anticipate changes in technology and to develop and introduce new and enhanced products on a timely basis will be a significant factor in the company’s growth, and help it remain competitive in the long term.

“Even though the company is in a strong place today, we continue to face several challenges. In the wall clock manufacturing industry, tastes and preferences are constantly changing along with progress in technology. We have to deal with such changes without losing our customer base,” he says.

Product range and expansion plans

Presently, Sonam Clocks makes a range of table and wall clocks at various price points across budget, mid-level, and premium categories.

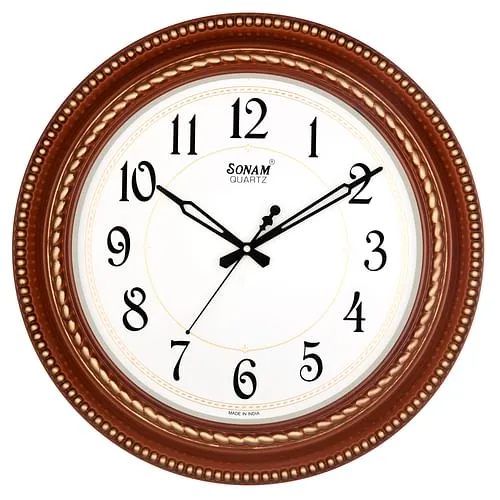

A Sonam wall clock

“Our clocks range from Rs 100 to Rs 1,800, and includes LED digital clocks, LCD clocks, light sensor clocks, pendulum clocks, musical clocks, rotating pendulum musical clocks, sweep clocks, office clocks, designer clocks, alarm clocks, table clocks, and regular clocks,” he says. The company also offers customised clocks in bulk quantities for corporate gifting.

Sonam clocks are primarily sold to dealers, retailers, corporates, and gifts and novelties stores, through which they reach end consumers. The products are sold under the brand names Sonam and Lotus. Sonam also sells clock movements and clock cases.

As Jayesh’s company now plans to expand and grow its revenue, it has to play a waiting game. It wants to pump in Rs 55 crore over the next few years to diversify its operations, but it has to hold back until the impact of the coronavirus pandemic wears out.

“We resumed production a while back, and we are taking precautions and adhering to the guidelines to ensure our employees’ safety. With the orders coming in from the export markets, we are hopeful of resuming mainstream operations soon,” he says.

He adds that customers are now evolving to appreciate fine craftsmanship over function in a clock. Further, the increasing demand for digital clocks is limiting the sales of traditional analog wall clocks.

“As innovation is the need of the hour, the requirement of digital clocks is more, especially in hospitals and companies. In addition, ersatz Chinese clocks are a serious threat to the market. Despite their poor quality, the largely price-sensitive Indian consumer base is often drawn to their cheap prices,” he says.

Edited by Megha Reddy