This Bengaluru-based agritech startup aims to make India ‘atmanirbhar’ in silk production

Bengaluru agritech startup ReshaMandi’s platform and app connects the entire silk supply chain — from farmer to manufacturer — seamlessly and with complete transparency.

India is the second-largest producer of silk in the world after China and the market is estimated to have been worth Rs 266 billion in 2019.

The Central Silk Board — a part of the Ministry of Textiles — estimates that the sericulture industry is one of the largest employers in the country, with activities spread across 52,360 villages, employing 9.1 million Indians in FY19.

The ban on Chinese products has provided a fillip for the Indian sericulture industry. In February 2021, Union Minister for Textiles and Women and Child Development Smriti Irani highlighted that over Rs 2,000 crore had been allocated from the Union Budget for the development of sericulture under the Silk Samagra Programme.

Women process cocoons harvested from farms connected to ReshaMandi's network.

However, the industry is facing several challenges — from the early stages of egg production, cocoon creation, yarn, and fabric production, to the supply chain, with traders acting as middlemen who exploit the farmers and producers of the yarn.

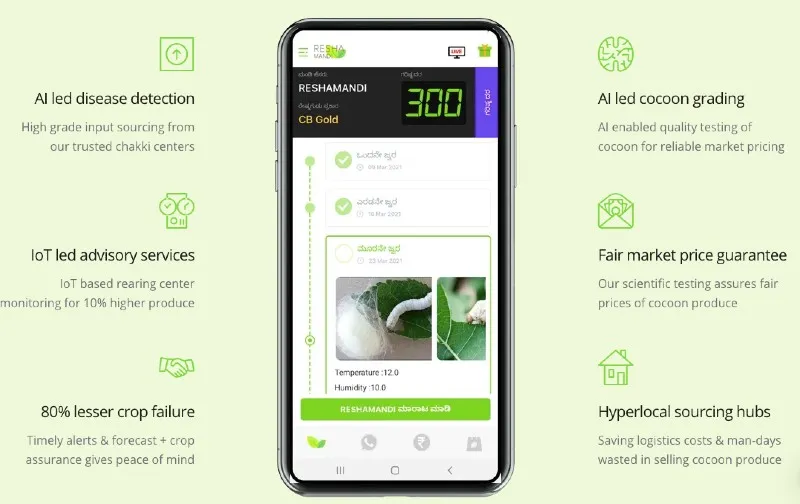

ReshaMandi, India's first silk agritech startup, is digitising India’s silk supply chain with AI and IoT-led digital ecosystems linking the farmer directly with the consumer. It is developing a full-stack network for organizing the silk supply chain, offering services such as quality monitoring, technical advice, high-quality inputs, and market linkages at each node.

Founded in April 2020, ReshaMandi works at the grassroots with sericulture farmers, fabric weavers, silk reelers, and retailers to help them get the best price for their produce.

The startup works directly with farmers to get the best market price while handling the entire supply chain.

The beginning

ReshaMandi was founded by Mayank Tiwari (CEO), Saurabh Agarwal (CTO), and Utkarsh Apoorva (Chief Business Officer). With 13 years of cross-domain experience across retail, ecommerce, and lean manufacturing, Mayank has worked across sales, marketing, operations management, and product development.

The inspiration for ReshaMandi first occurred to Mayank in early 2020 when the National Institute of Fashion Technology graduate was wondering how he could help promote one of India’s most treasured legacies — the silk industry.

He knew that something had to be done from the grassroots up. The Bengaluru native reached out to sericulture farmers in Karnataka — the largest silk producer in the country — and found they were very receptive to the idea of a ‘non-traditional’ platform that would help them.

“The day after the nationwide lockdown was lifted, I travelled 70 km from Bengaluru to Ramanagara — the silk capital of the world — to meet producers. I worked with them for over a fortnight, achieving market linkages, taking on the logistics, and assuring them a good rate. I was able to build a level of trust,” says Mayank, who drove daily for over a month from the farms to the producers to ensure in person that the links he had built remained unbroken.

He then presented the idea of building a platform that could connect the sericulture ecosystem to his friend Saurabh, who, at the time, was based in the US. Saurabh had previously built a multi-million dollar financial platform at CGI and a large-scale network software at CISCO.

Within seven days of that first conversation, Saurabh designed the entire ReshaMandi ecosystem. He then caught the next available flight to India.

Utkarsh — a serial entrepreneur who graduated from the Indian Institute of Technology, Delhi, also came on board inspired by the social impact the platform would achieve.

How it works?

ReshaMandi’s platform addresses the entire cycle of silk production — right from the harvest to the finished textile.

“Our services ensure that crops stay healthy via AI-based tracking, which has helped reduce crop failure by 80 percent, providing the farmer with higher production capacity, and eventually, higher revenue,” says Mayank, adding that ReshaMandi is the first player in the market to build a sustainable ecosystem, where the farmer can complete the entire cycle of silk work aided by technology.

The Operations Command Centre (OCC) is at the heart of the platform, providing IoT device-led data gathering and intelligence. Communication and alerts are in the local language, which makes it easier for the farmer.

The ReshaMandi platform offers support across the supply chain from the farmers to the manufacturers

The ReshaMandi Super app connects different stakeholders across the supply chain. The platform is a single-stop solution for ingestion of all IoT data, AI/ML data, providing linkages across verticals, integrations with fintech partners, and marketplaces. Digital payments are also integrated with gateways performed via a proxy.

For the stakeholders, the startup offers insights across the value chain. These include updates on weather and soil quality and how it could impact the cocoons, market linkages of both input procurement (cocoon) and selling output (yarns), and maintaining ledgers, information on best practices, and purchasing machine tools, etc., for weavers.

Today, ReshaMandi connects over 3,000 farms and deals in over 10 metric tonnes of cocoons daily.

Challenges

However, the past year has not been without its challenges, which include distrust between stakeholder communities due to the presence of middlemen, and a lack of transparency with pricing, leading to exploitation across the value chain.

In fact, the pandemic also impacted the entire production chain.

“As with any industry, COVID-19 has had an impact on the silk supply chain in India. We have seen a slight reduction in crop production due to the inability of the farmers to sell their stock on time, largely due to transportation constraints. If one part of the supply chain sees a reduction in production, there is an impact across the supply chain,” says Mayank.

He clarifies that despite the downturn in production volumes, the supply chain has been largely unaffected, and it is business as usual. This is partly due to the resilience of the stakeholders and ReshaMandi acting as a facilitator, giving them easy access to sell and procure requirements via the app.

Mayank adds that the startup managed to gain the trust of farmers by showing results.

“The farmers are willing to give technology a chance, and when we work with them to improve their crop yield, it helps them in early disease detection and prevention and enables them by providing easy access to market linkages, assured payments, and more. We have been able to create long-term partnerships with all stakeholders of the supply chain,” he says.

He shares the example of ReshaMandi’s first customers — Prabhakar Reddy and Srinivas Reddy — farmers from Bengaluru’s Sarjapur area.

“They believed in me from Day 1 and invited me into their homes. When they realised I did not speak Kannada, they tried a mix of Hindi and English to understand my vision. I was able to get them better rates for their produce, and they spoke about ReshaMandi to other farmers as well. They are still actively involved with us,” says Mayank.

He also speaks about Kaleem, a reeler, who has been with the startup since the beginning. He now relies entirely on ReshaMandi for cocoons without having to go to the market.

Just a year into operation, ReshaMandi recently raised $1.7 million in seed funding. Mayank — who wants to make India entirely self-reliant in silk production with transparency across the supply chain — says the funds will help strengthen the platform. It also plans to expand to other silk hubs like Tamil Nadu and Maharashtra.

“The ban on Chinese yarn imports has led to stakeholders increasing their production. The impact has been huge. Chinese yarn had high demand in India despite the quality, not being on par with Indian yarn. The main challenge was low production. Now, we want to fix this trend and take India to the top of the table,” says Mayank.

Edited by Suman Singh

1553156987557.png?fm=png&auto=format&h=100&w=100&crop=entropy&fit=crop)